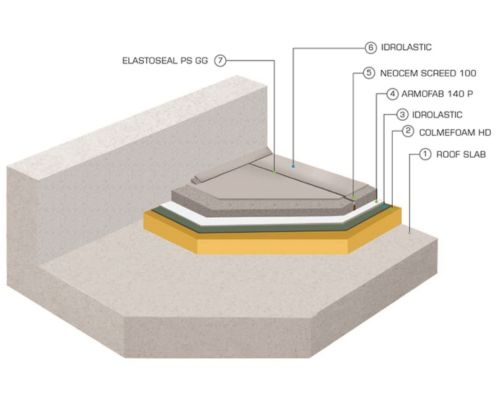

COMBO ROOF SYSTEM (METHOD OF STTAMENT)

COMBO ROOF SYSTEM

- Cleaning of dust and debris on the roof area using compressed air.

- Polyurethane foam spray: Supply and apply approximately thickness of average 70mm polyurethane

foam with density 40kg to 45kg. - Rubberized coating: Above completion of polyurethane foam application, Rubberized coating shall be

applied over entire foam to protect it from UV rays till the water test procedure is completed. - Flood Testing the Roof: Once acrylic UV coating is completely dried (minimum 24 hours), flood test will

be done by main contractor. - Separation Layer: Above the rubberized coating 120 gms/m2 geo textiles alaf., the filter membrane will

lay down as separation layer with overlap 10cm. - Preparation of Panels: On the geo textile the flexible board 2 * 3 meter panels will be made in slopes

for screed. - Screed: Supply and application of a layer of ready mix screed to slope of average 80mm thick. And

skirting will be done around parapet walls and AC foundations. - Filling Sealant into the Expansion Joints: After stability of screed the flexible board will be removed

from the joints and filled with single component of polyurethane sealant having the backing rod inside. - Foundation’s Waterproofing: All AC foundations & Water tank Foundations’ top coating will be done

horizontally and vertically. - Polyurethane coating: Finally, the Polyurethane Top Coating (with SRI Value more than 78%) will be done as protection and final finished layer to give attractive and smooth look on the roof top.